- All Solutions

- Temperature Control & Biostorage

Worried About Temperature Excursions?

We're here to mitigate temperature excursions during transportation. We use the best Vacuum Insulated Panel (VIP) packaging, combined with advanced technology, to ensure optimal conditions for your shipments. With a centralized pre-conditioning process and real-time monitoring, we actively safeguard the integrity of your goods throughout the journey.

Precise Temperature Control with BioTouch

Labs, hospital networks, CROs, and biopharma organizations rely on BioTouch’s logistics and storage solutions to uphold regulatory compliance, maintain precise temperature control, and safeguard the integrity of critical specimens and products throughout transportation and handling.

Packaging & Preconditioning

- Advanced Vacuum Insulated Packaging

- Passive & Active Solutions

- Containers: Pallet, Tote, & Parcel

- Controlled Room, Refrigerated, Frozen, & Dry Ice

Transportation

- Complete Chain of Custody

- Carrier Management & Courier Network

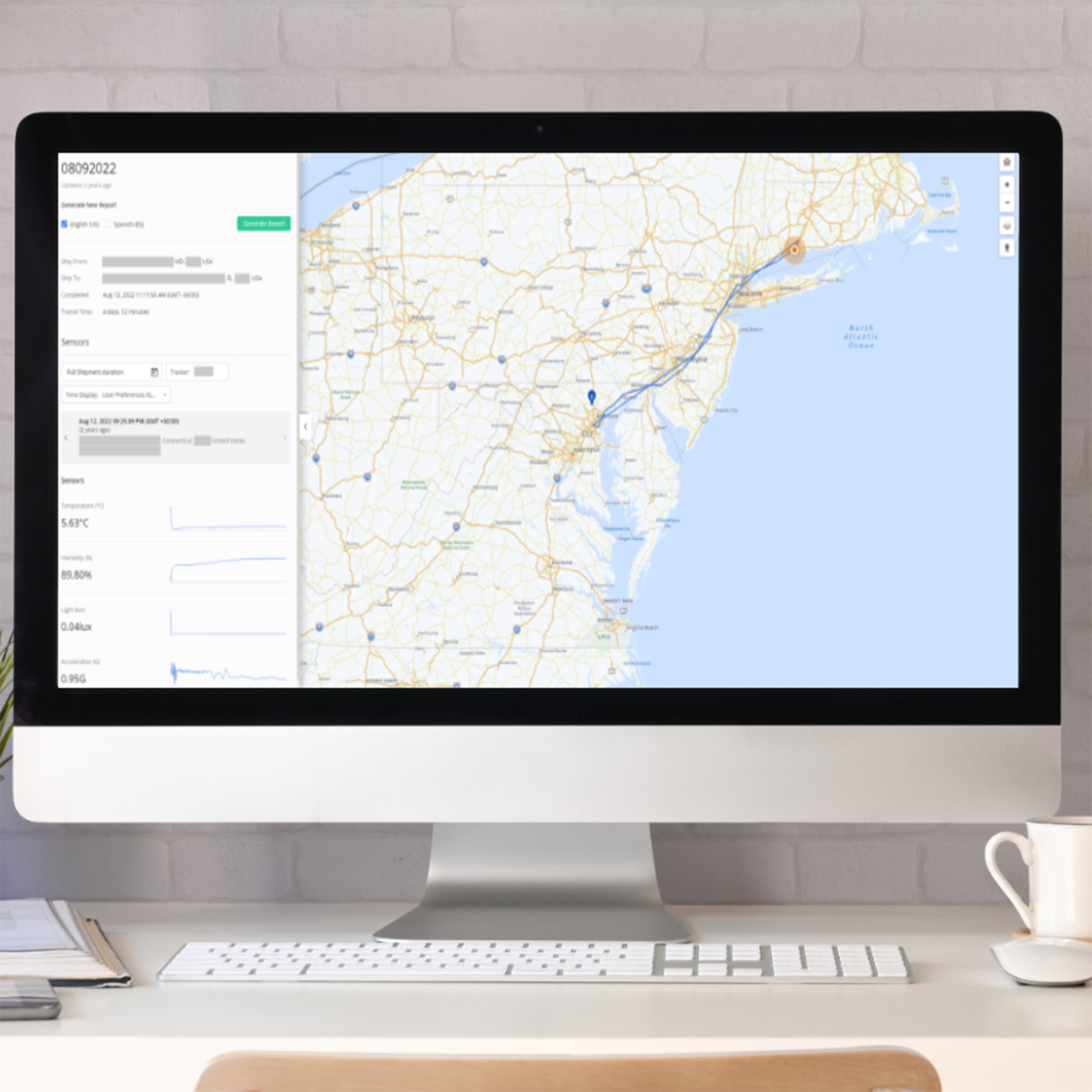

- Data Logging: GPS & Temperature Tracking

- 24-Hour Expedited Solutions

Command Center

- Control Tower Capabilities

- Proactive Monitoring & Intervention

- Visibility & Trace

- Dashboard-Driven Insights

Biostorage

- Refrigerated, Cryogenic, & Nitrogen

- FDA, GxP, ICH, & cGMP Compliant

- High Volume & Scalable

- Redundancy, Alarms, & Access Control

Temperature-Controlled Solutions

There Are Some Things You Just Can’t Control — Temperature Isn’t One of Them

Regain Control

Complete chain of custody from packaging, to transport, and return.

Improve Turnaround Time

With dedicated couriers and operations ensuring 24-hour placement of packaging once order is received.

Proactively Monitor

Each shipment is visible to you, using geo-location and temperature sensors so you can monitor at every step.

Temperature Control vs Cold Chain

Temperature Control

vs

Cold Chain

Precise

Temperature Controlled (TC) uses a qualified packaging solution, which maintains a precise range of temperatures for a specific duration of time.

Imprecise

Cold Chain is an imprecise method of regulating temperature, using refrigerated or frozen gel packs to keep materials cooler.

Controllable

+15C to +25C: Controlled Room Temp

+02C to +08C: Refrigerated

-15C to -25C: Frozen

-60C to -90C: Dry Ice

No Control

No method of control.

Strong

Mitigate temperature excursions.

Limited

Limited sample integrity.

Temperature Control Solutions Built for Your Healthcare Organization

Temperature Integrity

-

Using the best VIP packaging on the market.

-

Preconditioning processes are carefully managed at a centralized Temperature Service Center (TSC).

-

Active alarms to notify us when a shipment is approaching the limits of the required temperature range.

Responsiveness

-

Quickly and easily place orders with our user-friendly portal.

-

Our Integrated Carrier Network with dedicated carriers and a fleet of more than 3,000 couriers solely focused on medical transportation, we get your package where it needs to go.

-

Mitigate temperature excursions with timely communication.

Economic Value

-

Our dedicated experts deliver more than 6,000 medical kits every day, which means you are more than likely already on our route.

-

Need tailored solutions? Our team can design Temperature Control services and solutions customized to your specific needs.

Why BioTouch?

Mitigate temperature excursions and costly disruptions. Our technology tracking solution provides real-time geolocation and temperature data for each package, so you CAN control the temperature.

-

Increased Visibility

Improve your specimen tracking delivery and analytics, with 24-hour placement of packaging once an order is placed.

-

Packaging Expertise

We only use high-quality VIP Packaging that is carefully preconditioned at a centralized facility and proactively monitored every step of the way.

-

Improve Workflow & Reduce Costs

As your primary resource for all your laboratory needs, you will have access to an extensive offering of packaging solutions at a competitive price, plus all other healthcare logistics solutions you may need.

FAQs

Have Questions? Get Answers

What is temperature-controlled shipping?

Temperature-controlled shipping involves maintaining a specific climate environment for a set duration of time. Depending on what type of commodities are being shipped, different temperature ranges are required. Those temperature ranges vary and are often described as controlled room temperature (15°C to 25°C), refrigerated (2°C to 8°C), frozen (-15°C to -25°C), dry ice (-50°C to -90°C), or cryo (-150°C to -190°C).

How does BioTouch ensure temperature control during transportation?

BioTouch ensures temperature integrity through a dedicated fleet, high-quality packaging, geo-location, and temperature sensors, actively monitoring and providing economic value in medical kit transportation.

Can you monitor shipments in transit?

Yes, our top priority is equipping our operations team with dynamic data loggers to actively monitor every package in real time. When a package is getting too hot or too cold, data loggers will send an alert and our logistics team can take action. We utilize telemetrics to populate the geographical coordinates and internal temperature of each sender, employing a blend of GPS, Cellular, and Wi-Fi networks.

Do you have temperature testing capabilities for shippers?

Yes, we can simulate any shipping profile, including customer-developed extreme weather environments or industry standard profiles.

What temperature control packaging do you offer?

We offer a range of packaging options to accommodate all specimen shipping requirements, including refrigerated, ambient, frozen, and NanoCool (temperature-controlled). Temperature ranges vary and are often described as controlled room temperature (15°C to 25°C), refrigerated (2°C to 8°C), frozen (-15°C to -25°C), dry ice (-50°C to -90°C), or cryo (-150°C to -190°C).

What is NanoCool?

NanoCool is a type of shipper that offers 2℃ to 8℃ temperature ranges and covers durations of 48 to 92 hours.